+86 18531742341

+86 18531742341

Leave Your Message

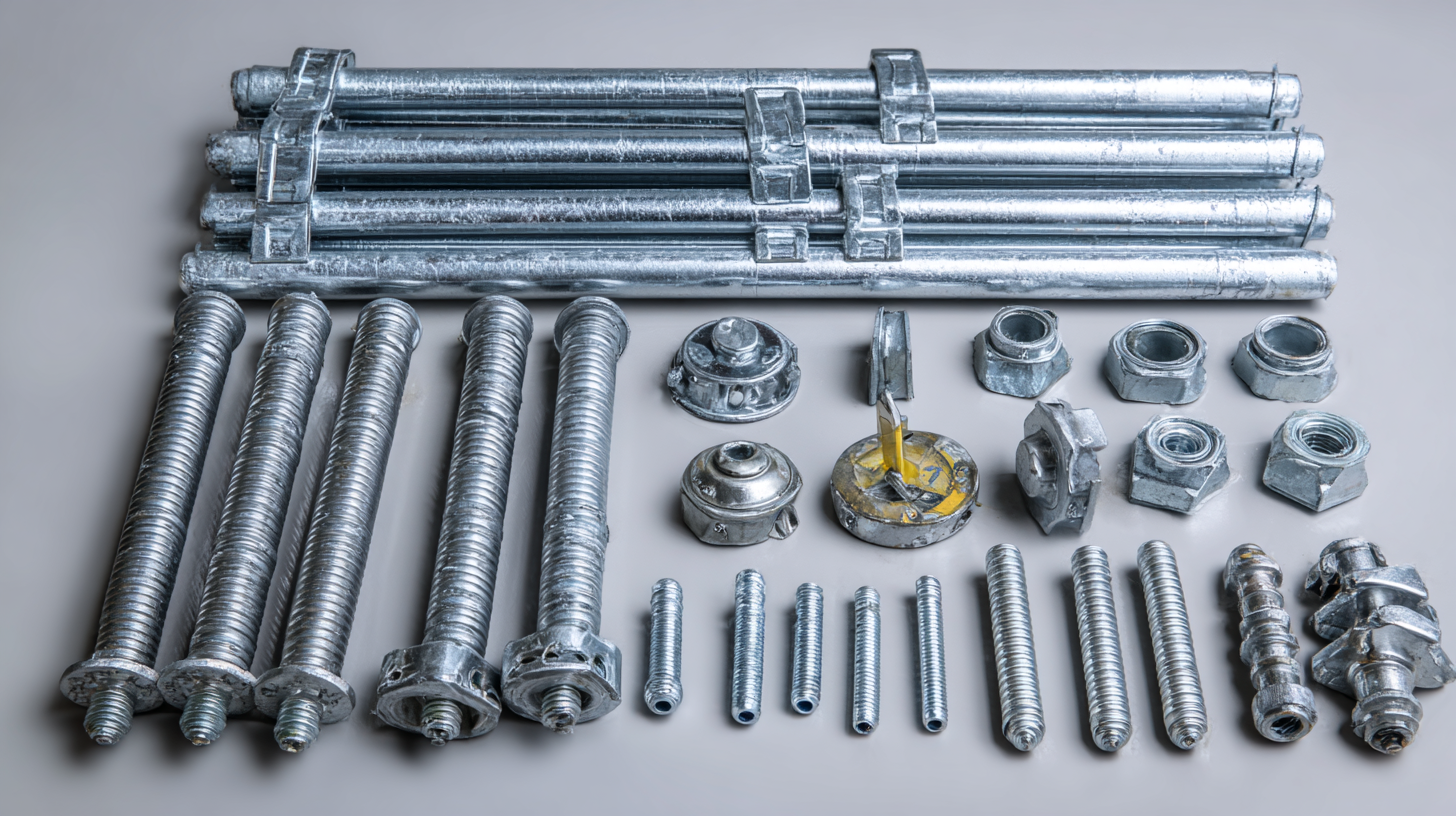

The global scaffolding market has experienced significant growth, projected to reach USD 4.35 billion by 2026, with an annual growth rate of approximately 5.5% during the forecast period. As construction demands escalate, the importance of high-quality scaffolding components cannot be overstated. China, recognized as a leading manufacturer in the sector, plays a pivotal role in supplying innovative and robust scaffolding solutions that adhere to international standards. To navigate this competitive landscape, industry professionals must employ a meticulous checklist to evaluate the quality and compliance of scaffolding components sourced from Chinese manufacturers. This approach not only ensures safety on construction sites but also enhances operational efficiency and project timelines. In an era where construction quality is paramount, understanding the benchmarks for scaffolding components will empower stakeholders to make informed purchasing decisions.

In the rapidly evolving construction industry, ensuring the quality of scaffolding components is paramount. As businesses seek reliable partnerships with manufacturers, identifying key metrics for quality becomes essential. According to a report from the International Association of Scaffold Manufacturers (IASM), over 60% of construction accidents related to scaffolding arise from the use of substandard materials. This statistic underscores the importance of partnering with credible suppliers that prioritize safety and reliability.

When evaluating potential suppliers, consider the following tips: First, assess their compliance with international safety standards, such as ANSI and OSHA guidelines. This compliance not only reflects adherence to industry norms but also ensures that the materials have undergone rigorous testing. Second, examine their production processes. A manufacturer with a transparent supply chain and established quality control measures—such as ISO 9001 certification—demonstrates a commitment to excellence.

Additionally, customer feedback and industry reputation play critical roles in supplier selection. Researching industry reviews and case studies can provide invaluable insight. A study by the Construction Industry Institute (CII) found that 75% of companies prioritize supplier reliability based on past performance and client testimonials, indicating that a proven track record can significantly influence your decision-making process.

The scaffolding manufacturing industry in China has seen significant growth and innovation over the past decade. As construction projects become more demanding, manufacturers are responding with advanced materials and designs that prioritize safety and efficiency. With a focus on high-quality production techniques, leading companies in China are now capable of producing scaffolding components that meet international standards, allowing them to compete on a global stage.

The scaffolding manufacturing industry in China has seen significant growth and innovation over the past decade. As construction projects become more demanding, manufacturers are responding with advanced materials and designs that prioritize safety and efficiency. With a focus on high-quality production techniques, leading companies in China are now capable of producing scaffolding components that meet international standards, allowing them to compete on a global stage.

When exploring the trends in this market, one key aspect is the increasing emphasis on sustainability. Manufacturers are now more aware of their environmental impact and are adopting eco-friendly practices in their production processes. This not only enhances the reputation of these companies but also aligns with the global push toward sustainable construction.

Tip: When selecting scaffolding components, always choose suppliers who prioritize quality control and sustainability in their manufacturing practices. This ensures that you not only get reliable products but also contribute to environmentally responsible development. Additionally, keeping abreast of technological advancements in scaffolding can help businesses stay competitive and meet the evolving needs of the construction industry.

When sourcing scaffolding components from manufacturers in China, understanding the certifications that suppliers hold is crucial. ISO (International Organization for Standardization) and CE (Conformité Européenne) certifications signify that a company adheres to rigorous quality and safety standards. According to a recent report by MarketsandMarkets, the global scaffolding market is projected to reach $XX billion by 2027, with increasing demand for certified products driving this growth. Thus, choosing suppliers with these certifications not only ensures product quality but also mitigates risks associated with compliance and safety.

One of the key benefits of partnering with ISO-certified manufacturers is their commitment to continuous improvement and customer satisfaction. The certification process requires companies to undergo regular audits, ensuring that they maintain high-quality manufacturing practices. Additionally, CE marking is mandatory for certain products sold in the European Economic Area, signifying conformity with health, safety, and environmental protection standards. This is vital during procurement, as non-compliance can lead to significant legal issues and project delays.

Tips for selecting scaffolding suppliers include verifying their certification documents and assessing their production capabilities. Requesting detailed quality management reports can also provide insights into their operational processes. Furthermore, consider the supplier's experience in the industry, as established companies with proven track records are more likely to deliver unmatched quality and safety in their products.

When selecting scaffolding components, understanding the balance between quality and price is crucial. According to a report by MarketsandMarkets, the global scaffolding market is projected to reach $33.2 billion by 2025, driven by rapid urbanization and infrastructure development. This growth highlights the increasing demand for reliable scaffolding solutions that do not compromise on 安全性 or 结构完整性.

Chinese manufacturers are at the forefront of this market, providing high-quality scaffolding components at competitive prices. A study conducted by Mordor Intelligence indicates that price sensitivity remains a significant factor for buyers, with nearly 40% of companies prioritizing cost-effectiveness. However, this shouldn’t overshadow the importance of quality—components that adhere to the latest safety standards can prevent construction accidents and enhance project efficiency. As industries increasingly recognize the long-term savings associated with investing in superior materials, the conversation shifts from merely comparing prices to assessing overall value, encompassing safety, durability, and compliance with international standards.

Engaging with manufacturers in China, particularly in the scaffolding components sector, requires a strategic approach that fosters long-term partnerships. As China's economy transforms, marked by significant advancements in innovation and supplier capabilities, manufacturers are increasingly open to collaborations. By understanding their production capabilities and aligning with their business goals, companies can cultivate mutually beneficial relationships that enable them to leverage high-quality scaffolding products.

In the context of improving international relations, particularly with the U.S., organizations must navigate the current trade dynamics carefully. As the U.S. grapples with its competitiveness, the stable supply chains emerging from China present an opportunity for American firms to enhance their operations. By prioritizing transparent communication and understanding local business practices, companies can establish trust and create a foundation for enduring partnerships with Chinese manufacturers. This not only contributes to quality assurance in scaffolding components but also integrates both parties into a resilient global supply network.