+86 18531742341

+86 18531742341

Leave Your Message

In the ever-evolving construction industry, the effective use of scaffold clamps has become paramount in ensuring safety, efficiency, and structural integrity on job sites. According to the Occupational Safety and Health Administration (OSHA), improper scaffold use accounts for approximately 25% of all construction-related accidents. As projects grow in complexity and scale, leveraging innovative solutions for the optimal deployment of scaffold clamps can significantly mitigate risks and enhance productivity. Recent market analyses suggest that the global scaffolding market is expected to reach USD 55.3 billion by 2027, with an increased demand for high-quality, durable clamps tailored for various applications. This blog explores cutting-edge strategies and technologies that can transform how scaffold clamps are utilized in construction projects, aiming to maximize both safety and operational efficiency.

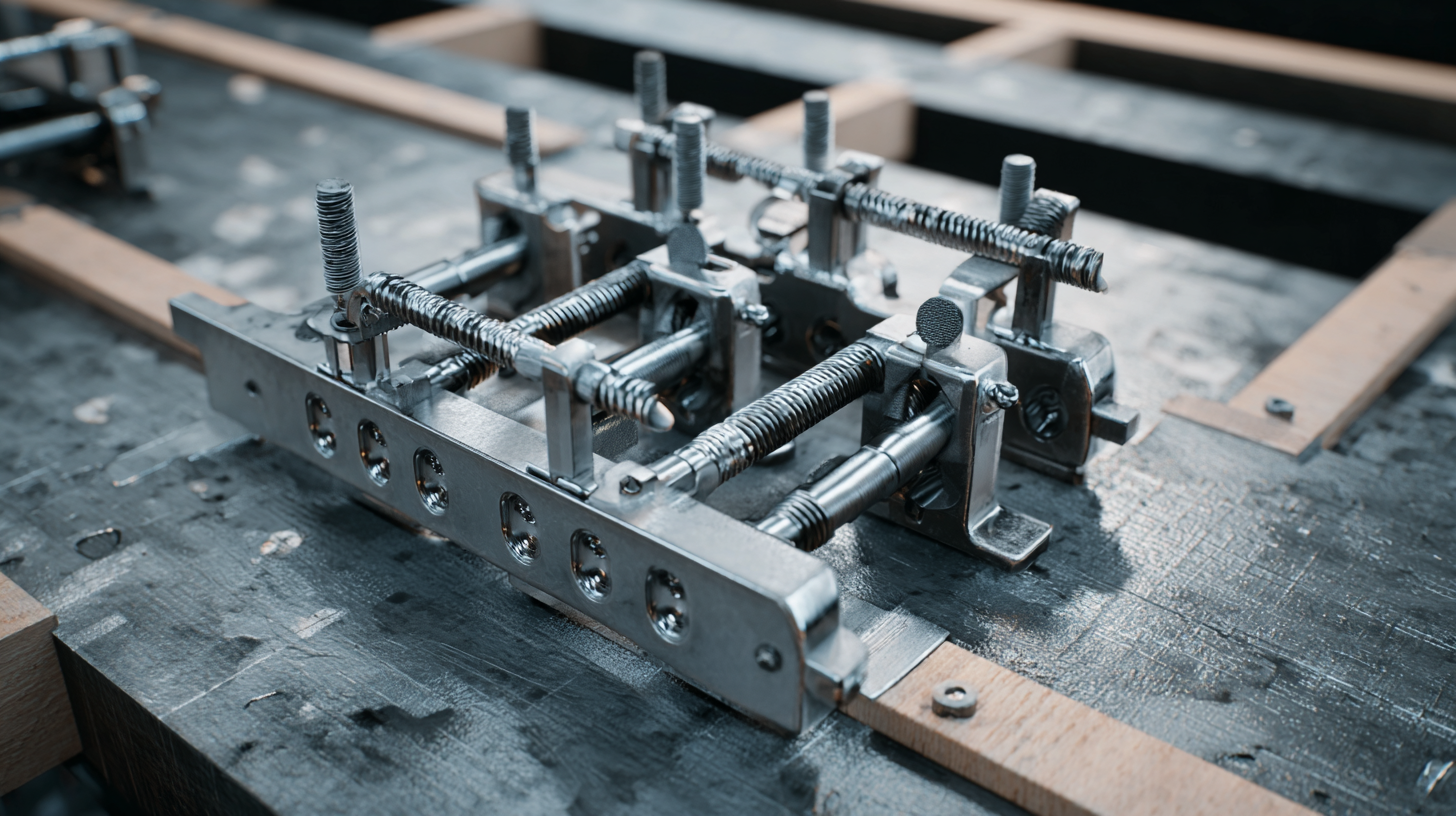

In the realm of construction, the durability and efficiency of scaffold clamps are paramount for ensuring safety and reliability on job sites. Recent innovations in materials technology have introduced bioinspired designs that draw inspiration from nature, enhancing the functional properties of scaffold clamps. These advanced materials, infused with intelligent engineering principles, aim to improve load-bearing capacities while simultaneously reducing weight. Utilizing concepts from intelligent soft robotics, the integration of flexible and adaptive materials can lead to scaffold clamps that not only endure the rigors of construction but also adapt to dynamic environments.

Furthermore, the exploration of sustainable materials such as bamboo is revolutionizing the approach to scaffold clamp manufacturing. Bamboo's intrinsic strength and resilience offer an eco-friendly alternative that aligns with modern sustainability goals in construction. By leveraging 3D printing technologies, manufacturers can create customized scaffold clamps that maximize efficiency and minimize waste. This innovative fusion of traditional materials with cutting-edge production techniques not only enhances the durability of scaffold clamps but also promotes sustainable practices within the industry, paving the way for smarter and more responsible construction projects.

In the rapidly evolving construction industry, the adoption of smart scaffold clamps is transforming safety and performance on job sites. As reported by the Occupational Safety and Health Administration (OSHA), improper scaffolding accounts for approximately 72% of all scaffolding-related accidents. By integrating technology into scaffold clamps, construction companies can enhance safety protocols and reduce the risk of injuries. Smart scaffold clamps equipped with sensors can monitor load levels and structural integrity in real-time, alerting workers to potential hazards before they escalate.

Moreover, advancements in materials science have led to the development of lightweight yet robust scaffold clamps that withstand harsh environmental conditions. According to a study by the Global Construction Review, the implementation of these innovative clamps can decrease labor costs by up to 25% while improving productivity by 15%. This is achieved through easier handling and faster setup times, allowing teams to focus on their core tasks rather than cumbersome equipment. As the construction sector embraces this technological shift, smart scaffold clamps are poised to redefine industry standards, enhancing safety and operational efficiency for all stakeholders involved.

The construction industry is gradually recognizing the importance of sustainable practices, and eco-friendly scaffold clamps are at the forefront of this transformation. With an increasing emphasis on green building materials, the use of sustainable scaffold clamps—crafted from recyclable materials and designed for reuse—is becoming essential. According to a 2022 report by the Global Energy and Sustainability Initiative, utilizing recyclable materials in construction projects can reduce waste by up to 30%, significantly decreasing the environmental footprint of a project.

Furthermore, innovative designs in scaffold clamps can enhance their durability and performance while minimizing the ecological impact. A recent study published in the Journal of Construction Engineering highlights that using modular scaffold clamps not only improves safety and efficiency on-site but also contributes to reduced material usage. By integrating sustainable scaffold systems, construction companies can align themselves with ISO 14001 standards for environmental management, ensuring compliance and potentially reducing costs associated with waste disposal and material procurement. As the industry shifts toward greener methodologies, the adoption of eco-friendly scaffold clamps reflects a commitment to a more sustainable future.

In modern construction projects, efficiency and safety are paramount,

particularly when it comes to the setup of scaffold clamps. To streamline installation processes, utilizing innovative techniques can significantly reduce setup time while enhancing safety measures on-site.

One effective method is the use of pre-assembled scaffold components. By integrating clamps with pre-cut and pre-drilled scaffolding parts, crews can quickly fit components together without wasting time on cumbersome assembly processes. This not only accelerates installation but also ensures that all parts are compatible and secure from the start.

Additionally, implementing a modular approach in the layout of scaffolding can further optimize clamp usage. By standardizing the design and materials of scaffold systems, teams can enhance versatility and adaptability on site. Modular designs allow for rapid configuration changes, which is especially useful in dynamic work environments. Training workers on these standardized techniques fosters a culture of safety and efficiency, as they become more familiar with the best practices for clamp setup. Enhanced focus on proper training and innovative solutions can lead to a significant reduction in accidents and improve overall project timelines.

Artificial Intelligence (AI) and robotics are transforming the construction industry, particularly in the realm of scaffold clamp design and usage. The integration of AI technologies facilitates predictive analytics, optimizing the deployment of scaffold clamps in various construction scenarios. According to a recent report, companies leveraging AI in construction management can enhance project efficiency by up to 30% while reducing waste significantly. This aligns with the growing trend of packaging 4.0, where technologies such as AI and the Internet of Things (IoT) streamline operations, ensuring that scaffold systems are utilized to their maximum potential.

Moreover, robotics play a crucial role in automating the assembly and disassembly of scaffold clamps, minimizing human labor and the risk of accidents on site. A study indicates that robotics can decrease labor costs by up to 25% and improve safety outcomes, leading to lower insurance premiums for construction firms. Alongside blockchain technology, which guarantees transparency and traceability in material sourcing, the adoption of these advancements fosters a sustainable and efficient construction ecosystem, paving the way for innovative solutions in scaffold clamp utilization and the broader construction landscape.

| Parameter | Traditional Methods | Innovative Solutions | Future Trends |

|---|---|---|---|

| Scaffold Clamp Material | Steel | Aluminium & Composite Materials | Smart Materials with Sensors |

| Installation Time | 2 hours | 1 hour | Less than 30 minutes with AI |

| Safety Compliance | Manual Checks | Automated Safety Sensors | Real-time Monitoring with AI |

| Cost | $200 per clamp | $150 per clamp | $100 per clamp with advanced tech |

| Weight | 4 kg | 2 kg | 1 kg with robotics integration |