+86 18531742341

+86 18531742341

Leave Your Message

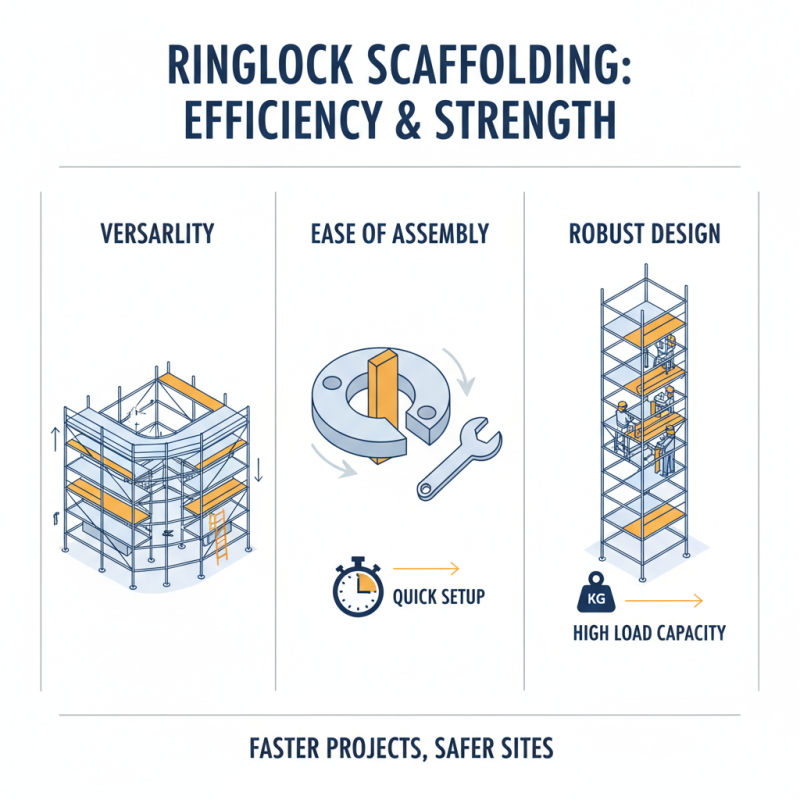

When embarking on construction projects, selecting the right scaffolding is crucial. Ringlock Scaffolding has gained popularity due to its flexibility and strength. According to industry reports, the global scaffolding market is expected to reach $70 billion by 2025. This surge in demand highlights the importance of choosing suitable scaffolding systems.

Ringlock Scaffolding stands out for its easy assembly and robust design. It can bear heavy loads, making it ideal for complex structures. However, some projects may require a different approach. Not all sites are the same, and what's suitable for one may not work for another. Understanding the specific needs of the project is essential.

Factors like site conditions, building height, and safety regulations play a vital role. Reliable data from the National Institute for Occupational Safety and Health shows that improper scaffolding contributes to 25% of construction-related injuries. Therefore, reflecting on the options available becomes necessary. Make informed decisions to enhance safety and efficiency on the job site.

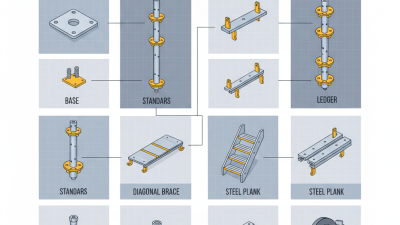

Ringlock scaffolding is becoming increasingly popular in construction projects. Its design offers versatility and strength. One of the key features of ringlock scaffolding is its ease of assembly. The system uses rings that allow for quick connections. This enables workers to set up the scaffolding efficiently. This can be a lifesaver for tight schedules.

The benefits extend to safety as well. With a secure locking mechanism, workers can feel confident using the structure. Additionally, the adaptability of ringlock scaffolding means it can accommodate various heights and designs. There may be concerns about weight distribution, which is crucial. Properly training staff on assembly will mitigate potential risks.

However, there are challenges. Ensuring the system is level can be tricky. Misalignment can create hazards. Frequent inspections are necessary for integrity. Moreover, not all projects may suit this system. Evaluating the specific needs is vital. Remember that what works for one project may not work for another. This requires careful thought and consideration before making a decision.

When selecting ringlock scaffolding for construction projects, understanding load capacity is critical. Each project has unique needs. Assess the weight of materials and equipment that will be placed on the scaffolding. This involves evaluating not just the total weight but also the distribution of that weight. An imbalance can lead to system failure.

Size matters significantly in scaffolding as well. Consider the height and width you require. Tall structures might need extra support beams. Narrow spaces require careful planning to ensure safety. There is a risk in overestimating size needs. It’s essential to measure accurately. Too large can lead to unnecessary material costs, while too small can compromise safety.

It's not uncommon to encounter issues during planning. Inexperience or hasty decisions can lead to mistakes. Sometimes, solutions only become apparent during setup. Reflecting on past projects can be beneficial. It helps in understanding what to adjust. Each project teaches valuable lessons about the importance of proper assessment and planning.

| Project Type | Load Capacity (kg) | Scaffold Size (m) | Optimal Configuration |

|---|---|---|---|

| Residential Construction | 2000 | 1.2 x 2.5 | Single Bay |

| Commercial Building | 3000 | 1.5 x 3.0 | Double Bay |

| Industrial Project | 4000 | 2.0 x 3.5 | Multi-Bay |

| Infrastructure Development | 5000 | 2.5 x 4.0 | Custom Configuration |

When selecting ringlock scaffolding, safety standards and compliance are critical. Regulations vary by region but aim to minimize accidents. According to the U.S.

Occupational Safety and Health Administration (OSHA), falls account for 33% of construction fatalities. Proper scaffolding can significantly reduce these risks.

During evaluations, check if the scaffolding complies with local safety codes. Look for certifications that demonstrate adherence to national standards. For example, in the UK, elements should meet the British Standards Institution's BS 1139 requirements.

Regular inspections ensure that scaffolding remains safe and functional over time.

Tips: Always involve experienced personnel when assessing scaffolding safety. They can identify potential hazards. Invest in training for your team to understand safety standards thoroughly.

Remember, compliance should not be viewed as a box-ticking exercise. Reflect on your site’s unique needs to ensure that your scaffolding choices genuinely enhance safety and efficiency.

When selecting ringlock scaffolding suppliers, quality must come first. Inspect the materials used in their scaffolding systems. Look for durable steel that can withstand heavy loads. The right coating is also essential. It protects against rust and corrosion. Poor quality materials can lead to safety hazards on site. Always ask for detailed specifications.

Cost is another crucial factor. It's tempting to go for the cheapest option, but this can be a mistake. Sometimes lower prices indicate lower quality. Do a cost-benefit analysis. Compare different suppliers’ prices and the quality of their products. Often, a slightly higher investment leads to better safety and efficiency. Check for warranties and customer support, too. A supplier who offers these can be more valuable in the long run.

Don't forget about reviews from other users. They can provide insights into a supplier's reliability. If possible, visit job sites using their scaffolding. This firsthand experience can reveal practical issues. It's key to find a balance between cost and quality. Reflection on your choices is important. Your project's safety depends on it.

Regular maintenance and inspection of ringlock scaffolding are critical for safety and longevity. According to the Scaffold & Access Industry Association, improper maintenance leads to 65% of scaffolding-related accidents. Regular checks help identify wear, rust, or instability that could compromise the structure. Inspectors should look for missing pins, bent frames, and loose connections. These small details matter greatly.

In a study by OSHA, 35% of scaffolds fail due to a lack of proper maintenance. Inspections should occur before each use, especially after severe weather conditions. This proactive approach can prevent catastrophic failures. It’s essential to document all inspections. Keep a checklist to note any issues encountered and resolved.

Neglecting these practices can have dire consequences. Workers trust scaffolding for their safety. Regular maintenance builds confidence. However, the cost and time needed for inspections may lead some to skip them. This oversight can turn into a serious risk for workers and projects alike. Developing a routine for maintenance ensures not only compliance but also peace of mind for everyone on site.