+86 18531742341

+86 18531742341

Leave Your Message

In the dynamic world of construction, choosing the right equipment can significantly enhance safety and efficiency on site. One of the most dependable components in this arena is the Scaffold Tube. Industry expert, John Thompson, a renowned structural engineer, emphasizes, "Scaffold Tubes are the backbone of modern construction; their versatility and strength are unmatched." This insight underlines the essential role scaffold tubes play in supporting various types of scaffolding structures, crucial for safe and efficient project execution.

Scaffold Tubes offer numerous advantages that make them a preferred choice among construction professionals. Their design allows for easy assembly and disassembly, facilitating quick setup and teardown. Moreover, their compatibility with a wide range of scaffolding systems means they can adapt to different project specifications, from residential buildings to large commercial structures. As such, understanding the benefits of Scaffold Tubes not only helps in making informed purchasing decisions but also contributes to the overall success of construction projects.

In conclusion, the choice of Scaffold Tubes directly impacts the safety and productivity of construction operations. With various options available in the market, recognizing the advantages of these essential components is vital for construction managers aiming to streamline their projects while ensuring safety and structural integrity.

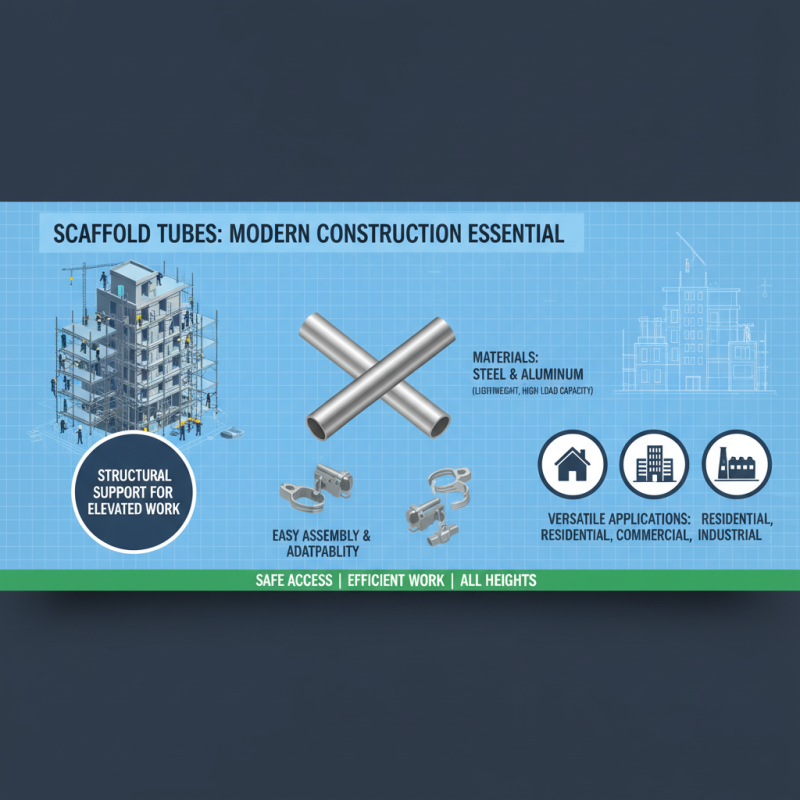

Scaffold tubes are essential components in modern construction projects, providing the structural support needed for safe and efficient work at elevated heights. Made primarily from steel or aluminum, these tubes are designed to bear heavy loads while remaining lightweight and easy to transport. Their uniform diameter allows them to be easily connected and assembled into a variety of scaffolding systems, adapting to the specific requirements of different construction sites. The versatility of scaffold tubes makes them suitable for a range of applications, from residential buildings to large commercial projects, ensuring that workers have safe access to elevated areas.

In terms of functionality, scaffold tubes serve several critical purposes in construction. They provide a secure platform for workers, enabling them to perform tasks at various heights without compromising safety. Additionally, they facilitate the installation of safety rails and other support structures, which further enhance the safety measures on site. The robust construction of scaffold tubes also ensures durability, allowing them to withstand harsh weather conditions and the rigors of construction work. By understanding the pivotal role of scaffold tubes, contractors and builders can make informed decisions that enhance operational efficiency and worker safety in their projects.

When it comes to construction projects, scaffold tubes have gained popularity for their numerous advantages over traditional scaffolding methods. One of the key benefits is their versatility. Scaffold tubes can be easily assembled and disassembled, allowing for adaptable configurations that can meet the unique needs of various projects. This flexibility not only enhances safety standards but also ensures efficient use of space on-site, an essential factor in busy construction environments.

Another significant advantage of scaffold tubes is their strength and durability. Made from robust materials, scaffold tubes can withstand heavy loads and adverse weather conditions, ensuring the safety of workers and the integrity of the structure being built. This reliability leads to reduced downtime, as fewer disruptions occur due to structural failures. Additionally, the ease of transport and storage of scaffold tubes saves both time and costs, making them an ideal choice for any construction team looking to optimize project management.

**Tip:** Always inspect your scaffold tubes for any signs of wear or damage before use. Regular maintenance checks can go a long way in ensuring safety and uptime on the job site.

**Tip:** Consider implementing a training session for your team on proper assembly and usage of scaffold tubes to maximize their effectiveness and ensure everyone is aligned on safety practices.

| Advantage | Description | Cost Efficiency | Safety |

|---|---|---|---|

| Versatility | Can be used in various construction scenarios. | Reduces overall project costs due to adaptability. | Improves safety by allowing custom configurations. |

| Durability | Made from high-quality materials to withstand harsh conditions. | Lower maintenance costs translate to savings. | Enhanced stability minimizes accidents. |

| Ease of Assembly | Quick and easy setup reduces labor time. | Savings on labor costs can be significant. | Supports rapid construction timelines without compromising safety. |

| Lightweight Design | Easier to handle and transport compared to traditional options. | Reduced transport costs due to lower weight. | Less physical strain on workers enhances safety. |

Scaffold tubes have gained popularity in the construction industry, particularly for their cost-effectiveness in large-scale projects. One of the primary advantages of using scaffold tubes lies in their durable construction, allowing for extensive reuse across various projects. Unlike other scaffolding materials that may be prone to wear and tear, scaffold tubes can withstand significant weight and pressure, reducing the need for frequent replacements. This durability translates into lower long-term costs, making them an economically wise choice for contractors.

Furthermore, scaffold tubes are easy to transport and assemble, leading to significant labor savings during the setup process. The lightweight nature of these tubes allows for a more efficient workflow onsite, which can be crucial in large-scale operations where time is of the essence. By reducing both material waste and labor costs, scaffold tubes provide a practical solution that aligns with the financial constraints often present in significant construction endeavors. This combination of durability, ease of use, and cost-efficiency makes scaffold tubes a preferred choice for builders looking to optimize their resources while maintaining safety and structural integrity on the job site.

Scaffold tubes are essential components in construction projects, offering significant safety benefits for both workers and the overall construction site. By providing a sturdy and reliable framework, scaffold tubes help to create secure platforms that minimize the risk of falls, one of the leading causes of injuries on construction sites. Their robust design and ability to support heavy loads ensure that workers can carry out their tasks safely at various heights, giving them the confidence to focus on their work rather than their safety.

Moreover, scaffold tubes facilitate efficient movement and access across construction sites. With a well-structured scaffold system in place, workers can swiftly transport tools and materials, reducing the likelihood of accidents caused by overcrowded or poorly organized workspaces. Additionally, the versatility of scaffold tubes allows for various configurations, accommodating different types of construction tasks while adhering to safety regulations. This adaptability ensures that regardless of the project's scale or complexity, the safety of workers is prioritized, ultimately leading to increased productivity and a safer working environment.

The chart above illustrates the multiple advantages of using scaffold tubes in construction projects, focusing on key aspects such as safety, durability, cost-effectiveness, flexibility, and ease of assembly. Each advantage is rated on a scale from 1 to 10, showcasing the significant benefits that scaffold tubes provide in enhancing worker safety and improving overall construction efficiency.

The environmental impact of choosing scaffold tubes for construction projects is significant, particularly in the context of sustainable building practices. Scaffold tubes, typically made of steel or aluminum, are known for their durability and reusability. According to a report by the World Green Building Council, utilizing materials that can be reused or recycled substantially reduces waste generation, which is critical in construction where waste accounts for nearly 30% of total waste produced globally. Scaffold tubes can be reused multiple times, leading to less material consumption and a smaller carbon footprint compared to traditional scaffolding systems.

Furthermore, the production of scaffold tubes involves processes that can be optimized for lower emissions. A study published by the Steel Construction Institute highlights that steel, when sourced responsibly, can have a lower life-cycle environmental impact compared to various temporary structures. Utilizing scaffold tubes manufactured from recycled steel not only conserves natural resources but also significantly reduces energy consumption, as recycling steel requires only about 25% of the energy needed to produce new steel. This shift to more sustainable options can contribute to achieving green building certifications, promoting eco-friendly practices within construction industries. Transitioning to scaffold tubes aligns with contemporary sustainable goals, ensuring that construction projects are both efficient and environmentally responsible.